You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Things built, torn down and other projects.(Pictures)

- Thread starter Orangeslice13

- Start date

buckfama

Volnation's official hillbilly

- Joined

- Aug 26, 2008

- Messages

- 3,653

- Likes

- 7,381

I haven't had time to do anything except work man. Lol

I just picked up 7 barns/buildings in middle Tennessee. I outbid a guy from Kentucky and another from Nashville. Another huge job. I'll attach a few pics of the biggest barn. It's around 90 feet long and probably 45 feet wide. Somewhere around 35 feet at the peak of the roof. Massive timber frame style barn which is almost unheard of in Tennessee or the south for that matter. It was built by German immigrants in the early 1900's.

No wedding date yet and have not wet a line.

I have to get this job finished so I can move onto this large job. I had to do some shuffling around to fit this one in, bit I've got it figured out. I still have Ohio barns to take down, plus over a dozen in Tennessee. I'm selling some retail. I'm wide open right now with no end in sight. It's a blessing and a curse. Lol

Note - to give some perspective on sizes in this barn, those floor joists are 2x10 oak, not 2x8 or 6 like normal. And the roof rafters are 2x6's instead of the 2x4's you normally see. They look tiny way up there. Lol. Barn is 100% oak. Huge 10x 10 and 10 x 12 oak beams for the frame.

buckfama

Volnation's official hillbilly

- Joined

- Aug 26, 2008

- Messages

- 3,653

- Likes

- 7,381

This is the job I'm trying to finish up now. A smaller barn with a log pen inside and a smaller shed/workshop.

Again almost 100% oak (oak is always the species I'm looking for).

This barn was built around the late 1880's. The log structure is staying in place. The way it was constructed, they left a lot of sapwood which insects love, so they are too buggy to be of any value to me. The 1x material on the other hand is first rate. Like I said they are mostly oak, with a few pieces of hickory and poplar thrown in.

I'll end up getting around 3000 board feet from these 2 small buildings. They were around 90% salvageable which was awesome.

I also have a general store across the street to reclaim which was built around 1910. Its loaded with oak too, with a little poplar.

After I finish these 3, it will have made 7 buildings total I've taken down for these folks. They have been pleased with my work. Word has spread and I have picked up a few just from word of mouth.

Also looked at a log cabin just down the road, but haven't made an offer on it yet.

Again almost 100% oak (oak is always the species I'm looking for).

This barn was built around the late 1880's. The log structure is staying in place. The way it was constructed, they left a lot of sapwood which insects love, so they are too buggy to be of any value to me. The 1x material on the other hand is first rate. Like I said they are mostly oak, with a few pieces of hickory and poplar thrown in.

I'll end up getting around 3000 board feet from these 2 small buildings. They were around 90% salvageable which was awesome.

I also have a general store across the street to reclaim which was built around 1910. Its loaded with oak too, with a little poplar.

After I finish these 3, it will have made 7 buildings total I've taken down for these folks. They have been pleased with my work. Word has spread and I have picked up a few just from word of mouth.

Also looked at a log cabin just down the road, but haven't made an offer on it yet.

Tin Man

Dirt's Childhood Playmate

- Joined

- Mar 9, 2015

- Messages

- 45,671

- Likes

- 43,546

buckfama

Volnation's official hillbilly

- Joined

- Aug 26, 2008

- Messages

- 3,653

- Likes

- 7,381

That big, oak, German barn has me drooling a bit, as do the 90 percenters

It's all top notch quality.

Here is the biggest reason I got the German barn. Like I said, there are 7 buildings total. The huge barn, another barn that is about 2/3 that size and 5 smaller buildings.

Neither of the other 2 buyers were interested in the smaller buildings, they only wanted the big barn. I agreed to remove all 7 and for 2 reasons..

1. You can't ignore your customers needs. They need all 7 gone, you remove all 7 regardless if the others aren't as profitable.

2. You can't ignore the smaller buildings because they can be profitable too. One of those 7 is a small barn that was used as a sawmill and a workshop. Neither of the other 2 guys even looked at or inside it.

In the loft was about 2000 board feet of sawn, dried lumber that had been up there for 50 years. There are 1x boards that are 20 inches wide and some 2x15 oak board, at least $4,000 worth of premium lumber that had never had a nail in it. All I have to do is back a trailer up and load it.

Those 2 smaller barns I'm working on now, most guys wouldn't look twice at either of them. I'll make nearly $8000 of those 2 small buildings. They aren't much to look at from a quick glance, but once you look a little closer, the quality of the wood is hard to ignore. Those 2 guys being short sighted cost them this job.

Getting these huge barns is great, but the small ones are just as valuable and add to the bottom line nicely.

I'm glad most are short sighted when it comes to these smaller structures and how they do business, it adds profit to my bottom line daily.

superdave1984

Repeat Offender

- Joined

- Aug 14, 2007

- Messages

- 8,014

- Likes

- 4,086

@Orangeslice13

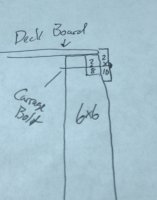

Not sure if these will show up. They are really light. I am not a draftsman. I read someplace that what I am talking about with the posts is a seat cut. There will be a ladder where the opening is on the side view.

Not sure if these will show up. They are really light. I am not a draftsman. I read someplace that what I am talking about with the posts is a seat cut. There will be a ladder where the opening is on the side view.

Last edited:

Orangeslice13

RockyTop is back, Let’s Go!!

- Joined

- Jan 2, 2011

- Messages

- 89,760

- Likes

- 99,582

superdave1984

Repeat Offender

- Joined

- Aug 14, 2007

- Messages

- 8,014

- Likes

- 4,086

Orangeslice13

RockyTop is back, Let’s Go!!

- Joined

- Jan 2, 2011

- Messages

- 89,760

- Likes

- 99,582

Oh, and there will be an actual tree involved. I am not going to attach anything to the tree though. It will go around the tree in one of the front corners.

Ok.

6x6 posts. No 4x4s. Absolutely notch as drawn. Put a carriage bolt through every post.

Spanning 8 feet you could use 2x6 but with a roof I wouldn’t. That’s a lot of weight. 2x8 joists and a 2x8 inner band. Use 2x10 for the outside band. Yes you want a double band even though it’s just a tree house. Put hangers on the joists and your good to go.

Also you won’t need the angle support if you notch and bolt the posts. Unless you like the look. Also put it on 16 inch centers.

I can’t wait to see the pictures

Orangeslice13

RockyTop is back, Let’s Go!!

- Joined

- Jan 2, 2011

- Messages

- 89,760

- Likes

- 99,582

Orangeslice13

RockyTop is back, Let’s Go!!

- Joined

- Jan 2, 2011

- Messages

- 89,760

- Likes

- 99,582

superdave1984

Repeat Offender

- Joined

- Aug 14, 2007

- Messages

- 8,014

- Likes

- 4,086

How would I do a double band if I notch the posts? Just add it to the inside? A 42" railing is nearly as tall as my kids. But probably better to be safe-ish. I originally thought about no railing at all. Being raised in the 70's and all.

This is good info. Slice is the man.

That is an option as well. I watched a youtube where a guy added a slide made out of plywood and a roll of aluminum. Pretty sweet.Will there be a slide?

This is good info. Slice is the man.

superdave1984

Repeat Offender

- Joined

- Aug 14, 2007

- Messages

- 8,014

- Likes

- 4,086

Tin Man

Dirt's Childhood Playmate

- Joined

- Mar 9, 2015

- Messages

- 45,671

- Likes

- 43,546

Orangeslice13

RockyTop is back, Let’s Go!!

- Joined

- Jan 2, 2011

- Messages

- 89,760

- Likes

- 99,582

The 2x8 sits in the notch. The 2x10 covers the outside and covers the decking.How would I do a double band if I notch the posts? Just add it to the inside? A 42" railing is nearly as tall as my kids. But probably better to be safe-ish. I originally thought about no railing at all. Being raised in the 70's and all.

That is an option as well. I watched a youtube where a guy added a slide made out of plywood and a roll of aluminum. Pretty sweet.

This is good info. Slice is the man.

I’ll draw a picture

Orangeslice13

RockyTop is back, Let’s Go!!

- Joined

- Jan 2, 2011

- Messages

- 89,760

- Likes

- 99,582

superdave1984

Repeat Offender

- Joined

- Aug 14, 2007

- Messages

- 8,014

- Likes

- 4,086

Orangeslice13

RockyTop is back, Let’s Go!!

- Joined

- Jan 2, 2011

- Messages

- 89,760

- Likes

- 99,582

And put a bunch of lag bolts through the 2x10 all the way around? Or just at the posts? Seems like I would need a couple every couple feet all the way around. Or am I overthinking this?

Bolts at through the post. Nail(or screw) the outer and inner band together 3 every 16 inches. Top to bottom pattern.

Build it and put the decking boards on then put the outer bsnd on last.

volfanbill

pack light and love heavy…

- Joined

- Sep 6, 2006

- Messages

- 43,331

- Likes

- 29,334

superdave1984

Repeat Offender

- Joined

- Aug 14, 2007

- Messages

- 8,014

- Likes

- 4,086

Would there be any benefit to using some liquid nails between the bands or is that overkill? Or would it even stick to treated lumber?Bolts at through the post. Nail(or screw) the outer and inner band together 3 every 16 inches. Top to bottom pattern.

Build it and put the decking boards on then put the outer bsnd on last.

Orangeslice13

RockyTop is back, Let’s Go!!

- Joined

- Jan 2, 2011

- Messages

- 89,760

- Likes

- 99,582

tnuhcvols

Time for a Scooby snack

- Joined

- Dec 6, 2012

- Messages

- 9,791

- Likes

- 11,199

superdave1984

Repeat Offender

- Joined

- Aug 14, 2007

- Messages

- 8,014

- Likes

- 4,086

buckfama

Volnation's official hillbilly

- Joined

- Aug 26, 2008

- Messages

- 3,653

- Likes

- 7,381